Hydraulics

Springs and pressings for hydraulic applications and systems. Designed for durability and precision to meet the highest industry standards.

Home » Industries » Hydraulics

Highest Quality Springs for the Hydraulic Industry

When precision control is required, commonly demanded by applications across heavy construction machinery and advanced industries, hydraulics are often the solution.

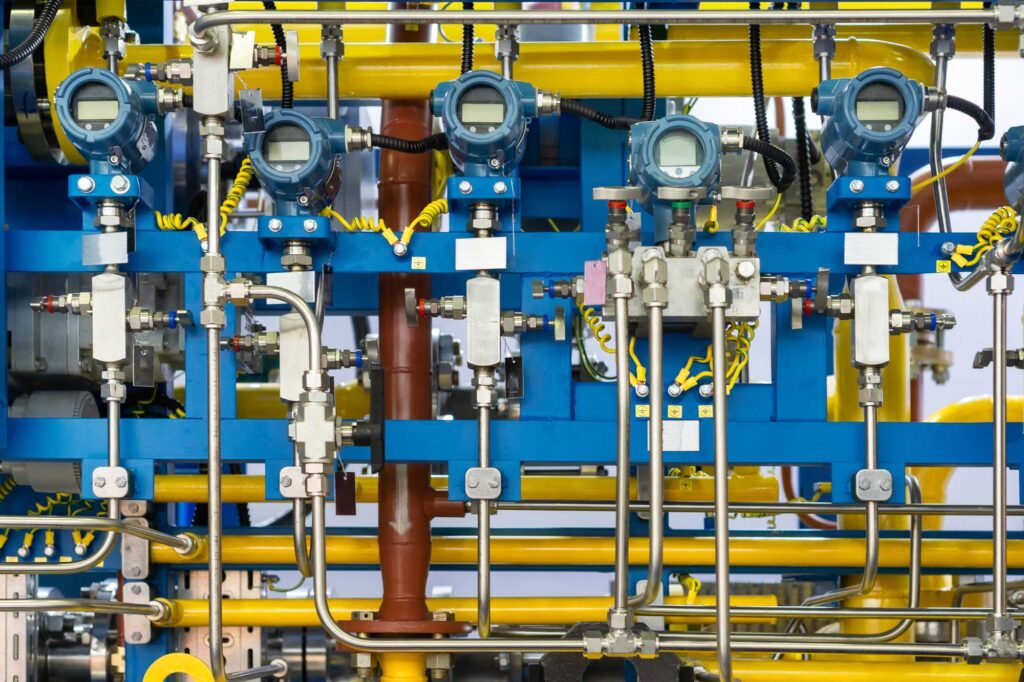

Hydraulics transform energy through fluids under pressure, transmitting a force through a closed circuit of valves, hoses, pumps, motors and cylinders.

Lesjöfors manufactures and supplies the hydraulic industry with state-of-the-art technical springs in all sizes and volumes, certified according to ISO standards. Regardless of the quantity and application, we offer innovative solutions for the manufacturing process.

With a strategically positioned global manufacturing network, we guarantee production efficiencies through our local sites. Our commitment to innovation drives continuous investment in cutting-edge technology, enhancing spring performance, durability, and customization – ensuring optimal solutions for hydraulic applications.

Do you have questions? Our team is here to help!

Write us an email to

Valve Control Systems

Springs and pressings play a critical role in hydraulic valve functionality, ensuring precise force application, pressure regulation, and long-term reliability. Our components are engineered for high-load applications and are manufactured to meet the most stringent tolerance and durability requirements.

Compression Springs

Pressing

Hydraulic valves are indispensable across many diverse industries including in industrial machinery, aerospace technology, the oil and gas sector and in heavy machinery across agriculture, mining and construction. They are part of high-pressure fluid control applications, ensuring precise regulation of hydraulic flow and pressure. These valves rely on compression springs and wave springs maintain accurate pressure control, reliable actuation, and smooth operation under extreme conditions.

We offer custom-engineered solutions for:

- Flow Control Valves

- Pressure Control Valves

- Directional Control Valves

Flow Control Valves

Used in hydraulic presses, lifting equipment, and fluid distribution systems (like hydraulic balancing valve for heating systems), these valves regulate flow rates to maintain efficiency and performance stability. Our high-precision compression and disc springs are manufactured using automated coiling, shot peening, heat treatment and washing processes, ensuring superior fatigue resistance and compliance with rigorous cleanliness requirements.

Our expertise in customization, material selection, and advanced manufacturing allows us to deliver reliable, high-performance solutions tailored to your hydraulic system requirements.

Compression Springs

Compression Springs

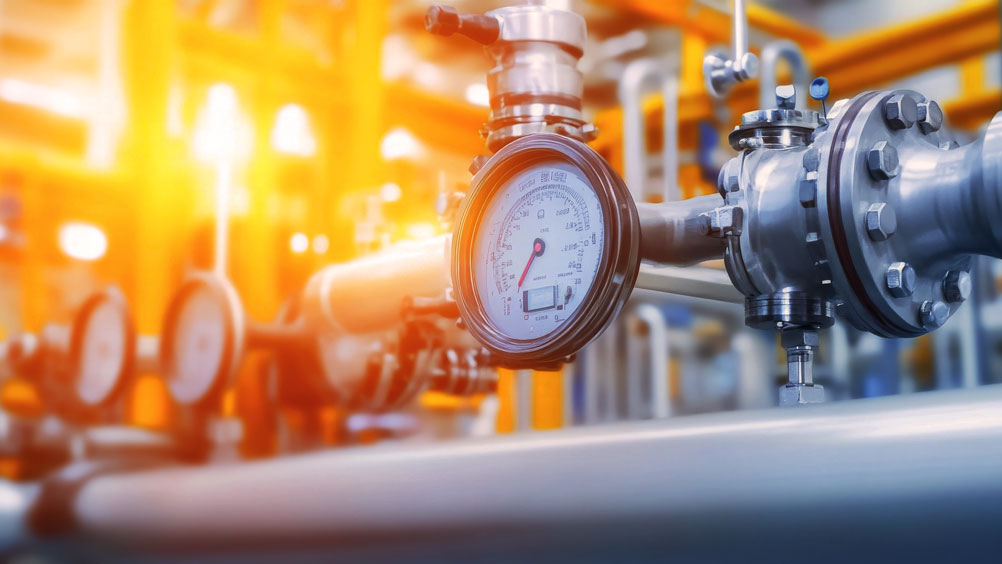

Pressure Control Valves

Found in hydraulic power units, construction machinery, and braking systems, these valves prevent system overloads and pressure spikes, e.g. in an exhaust system valve. Our coil springs are engineered for durability and reliability. Made from corrosion-resistant alloys, they undergo shot peening for enhanced strength and are rigorously tested under high-cycle loads to ensure a long service life. Each spring also passes strict cleanliness tests, arriving ready for immediate use.

Directional Control Valves

Used in hydraulic actuators, injection molding machines, and material handling systems, these valves switch fluid direction for smooth and precise movement, providing reliable actuation and precise force application for seamless hydraulic function.

Our precision-calibrated springs and pressings undergo stringent dimensional inspections, load testing, and automated quality checks to guarantee optimal performance.

Compression Springs

Compression Springs

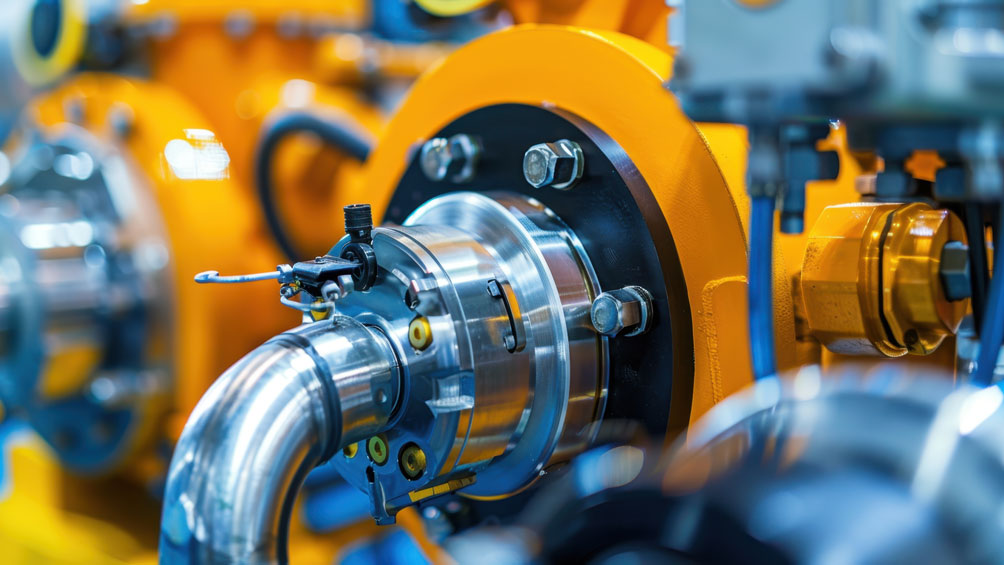

Hydraulic Pumps

A hydraulic pump transforms mechanical energy from a motor into hydraulic energy, creating flow and pressure in the system. The energy in the fluid is then used by the hydraulic motor and cylinder, converting hydraulic energy back into mechanical motion for industrial, automotive, and heavy-duty applications.

Hydraulic pumps, like the reciprocating piston and plunger pumps, the need for high quality springs with special performance requirements are essential for inlet and outlet valves, ensuring precise fluid regulation and reliable pressure control. Compression springs, disc springs and wave springs provide consistent force and fatigue resistance, while precision pressings and shims contribute to valve sealing and structural stability.

Our expert engineers can support you by calculating the optimal material grade and associated spring design, ensuring maximum durability and efficiency in demanding hydraulic environments.

Hydraulic Actuators

A valve actuator, also known as an actuator valve, functions as a control gateway, regulating the opening and closing of a valve within a hydraulic system. Integrated into the valve framework, the actuator control system automates and precisely manages fluid flow, making it essential for modern industrial and mobile hydraulic applications.

Our high-precision springs play a critical role in actuator performance, providing the necessary force for smooth, controlled movement. Whether in industrial automation, energy systems, or heavy machinery, our custom compression springs, disc springs and pressings ensure reliable force application and long-term durability. Through advanced material selection, strict quality controls, and precision manufacturing, we guarantee consistent actuator performance even in demanding hydraulic environments.

Compression Springs

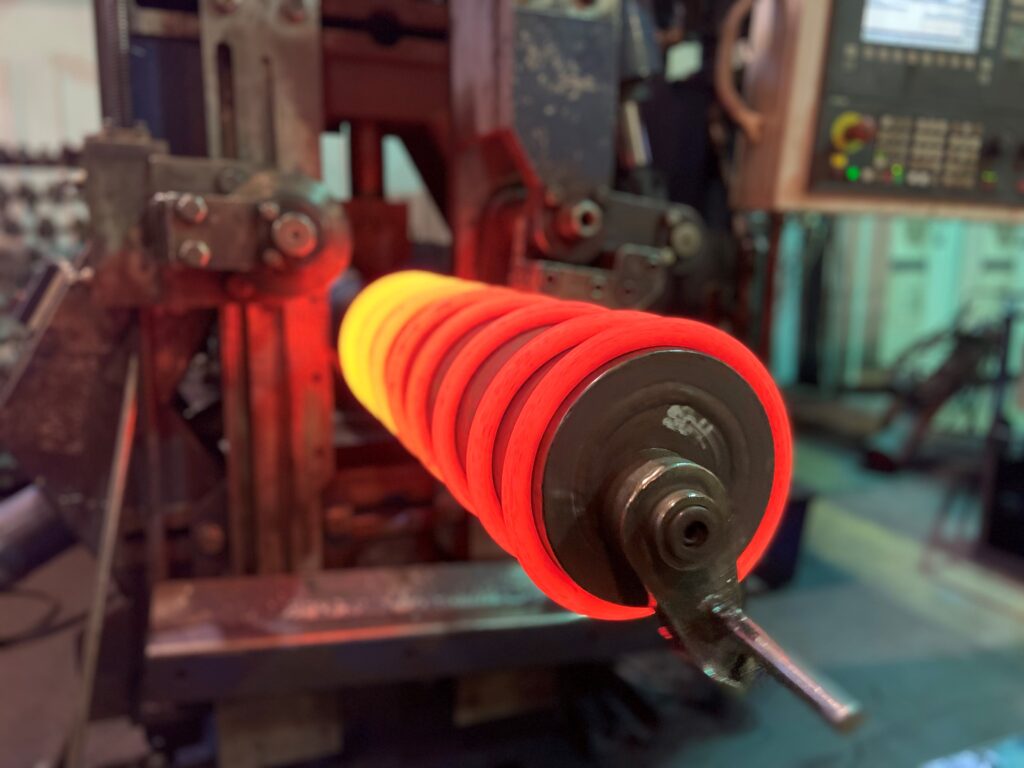

Heavy Springs for Hydraulic Systems

Some valve, actuator, pump and flow control applications require extra large springs, capable of supporting heavy loads. We call them ‘heavy springs‘.

We are market-leaders in heavy duty spring manufacture. With a 350 year manufacturing spring legacy, we provide the greatest expertise, in state-of-the-art production facilities, across hot and cold coiling CNC technologies, in compression torsion and tension spring manufacturing of large wire dimensions with a diverse range of steels, copper and titanium alloys as well as super alloys, such as Inconel, Hastelloy and Nimonic, that are especially resistant to high temperatures and corrosions.

We continually invest in the best and provide a competitive environment dedicated to quality, accuracy and customer satisfaction, guranteeing Lesjöfors as the premium partner for your heavy duty springs for valves, actuators and flow control.

As end-to-end manufacturers, we ensure top-tier quality and precision in spring production, utilizing CAD/CAM, 3D scanning, pre-stressing, shot peening, grinding, and powder coating. We customize length, force, movement, damping, connectors, color, and finish to meet your exact specifications. Our experienced specialists excel in theoretical modeling, stress analysis, and evaluating creep and fatigue performance, ensuring optimal durability and reliability in every component.

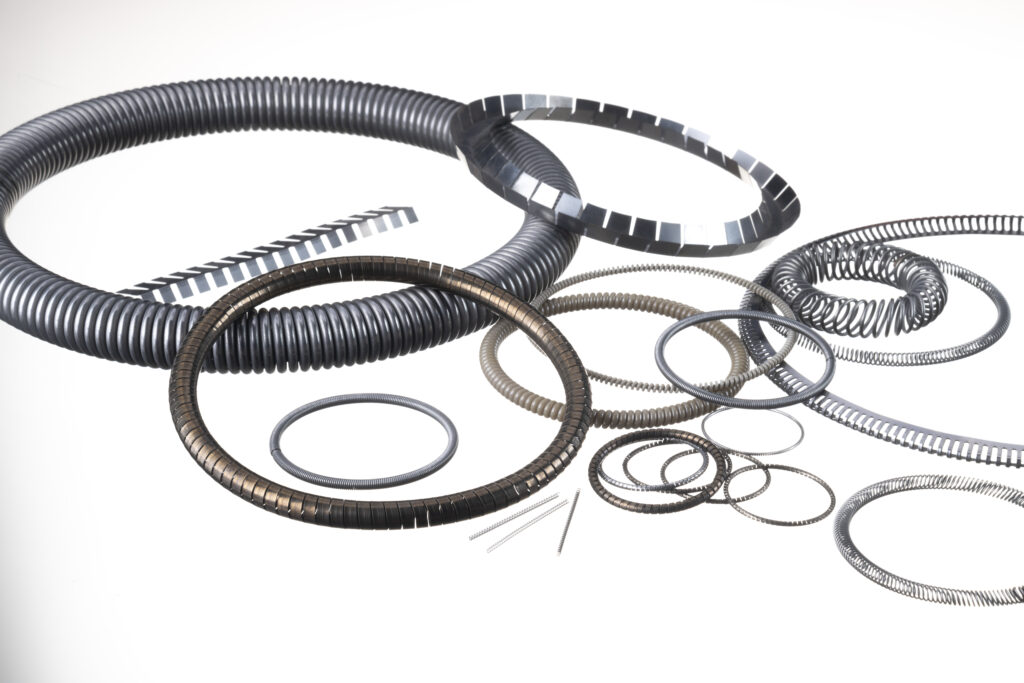

Spring Energised Sealing Solutions

Spring-energised sealing solutions ensure leak-proof connections, pressure stability, and durability in hydraulic systems. From cryogenic to high temperatures, and in chemically aggressive or high-pressure systems, they maintain performance and reliability to prevent system failure.

Each energising spring is designed for a specific sealing and retention challenge. Canted coil and garter springs deliver uniform radial force for high-pressure seals. Helical and meander springs add flexibility and responsiveness under varying pressure. Continuous top rail and anti-extrusion springs improve retention and prevent deformation. PEEK springs provide excellent chemical resistance and protect hardware from damage where contact occurs. Matching each spring type with advanced materials creates optimal solutions for static and dynamic applications in this wide range of environments.

Precision forming and strict quality control ensure every spring performs as required and delivers high-performance sealing, tailored to your needs.

Further questions? Get in touch!

Write us an email to

Frequently Asked Questions

A wide variety of valves are used across hydraulic systems, each performing a slightly different function. At their core, all hydraulic valves regulate fluid flow and are essential to the proper functioning of a system, with springs playing a crucial role in ensuring precise, efficient, and safe operational functions. Read more about how hydraulic valves work in this article [link].

The best spring for your hydraulic application depends on its function and operating conditions. Compression springs are commonly used in valves and actuators for controlled force application, while disc springs provide high-load capacity in pressure regulation systems. Gas springs offer smooth motion and damping in lifting or counterbalancing applications. For specialized needs, custom-engineered springs and pressings ensure optimal performance tailored to your system’s specific requirements. Reach out to our team and we will find the optimal solution for your application.

The durability of hydraulic springs depends on design, material quality and manufacturing processes. High-strength alloys, combined with various treatments enhance fatigue resistance, ensuring long-lasting performance.

When requesting a spring for a hydraulic application, key criteria include load requirements, dimensions, material, and environmental conditions. Specify the force, deflection, and operating pressure, as well as spring type (compression, disc, gas, etc.). Consider temperature, corrosion resistance, and fatigue limits to ensure durability. Providing details on application, mounting, and expected cycle life helps optimize design for maximum performance and reliability.

The right material for a hydraulic spring depends on load conditions, operating environment, and durability requirements. Oil tempered alloyed valve wire offers a high strength for heavy loads while patented spring wire is used for less demanding spring applications. Stainless or acid proof steel is commonly used for its corrosion resistance. We also offer a diverse range of super alloys (e.g. Inconel, MP35, Hastelloy, Elgiloy/Phynox, Nimonic) providing an enhanced resistance to high temperatures and corrosion extremes.

PEEK and other engineered polymers are ideal for chemical resistance and extreme temperatures. If the spring is exposed to high pressure, moisture, or contaminants, coatings and surface treatments can further enhance longevity and performance.

Sustainabiltiy in mind. With every innovation.

Sustainability is at the heart of our products and processes. We are committed to minimizing our environmental impact and have already taken significant steps toward a greener future. Learn more about our ongoing efforts and initiatives here.